Who let the heat out – why are heating systems inefficient?

Years ago, when we were busy installing biomass boilers we were excited and proud to be helping the UK heating profile change to one of sustainable practices and renewable fuels.

After a few heating networks were up and running we were able to analyse the results. We had an unpleasant surprise; overall system efficiency over the course of a year would be around 45% to 55%, well below our expectations.

Why are heating networks so inefficient?

The current design template is to deliver a constant temperature and constant flow of heat around the network. This is generally set at a temperature and flow rate that will meet the worst case scenario; when it is very cold outside.

Generally, that is defined as a few degrees Celsius below zero, depending on the location of the site in the UK.

That means that a fixed amount of energy is being converted into heat, regardless of whether the demand for that amount of energy is there or not. The hot water in the pipework is not actually leaving much of its heat at the point of use. So, rather than being used to heat the homes, offices and provide domestic hot water, that energy is being lost in the distribution pipework or going up the flue.

As you can imagine, the majority of time heating is required worst-case scenario conditions are not present e.g. it may be chilly but not freezing.

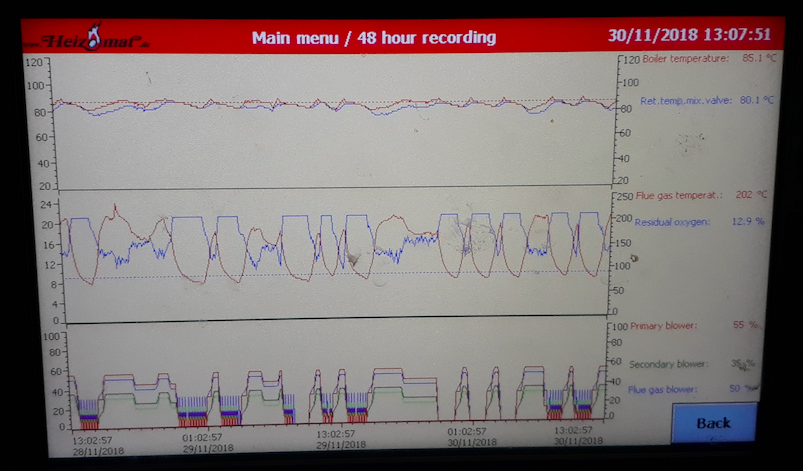

At these times the boiler is constantly cycling (turning on and off) to keep the water in the system at the constant set temperature but, as the actual heating demand is low, only a small amount of heat leave via the heat emitters e.g. radiators. The temperature of the water flow is much higher than need be.

Top section demonstrate narrow difference between the flow and return temperatures. Middle Section shows, ‘cycling’. Bottom section shows excessive use of electrical fans leading to wear and tear and higher energy bills.

Meanwhile by pushing the flow of water around the system so quickly (at a constant volume) the hot water does not have the chance to spread the heat from the radiator, cool down, and return to the boiler at a lower temperature.

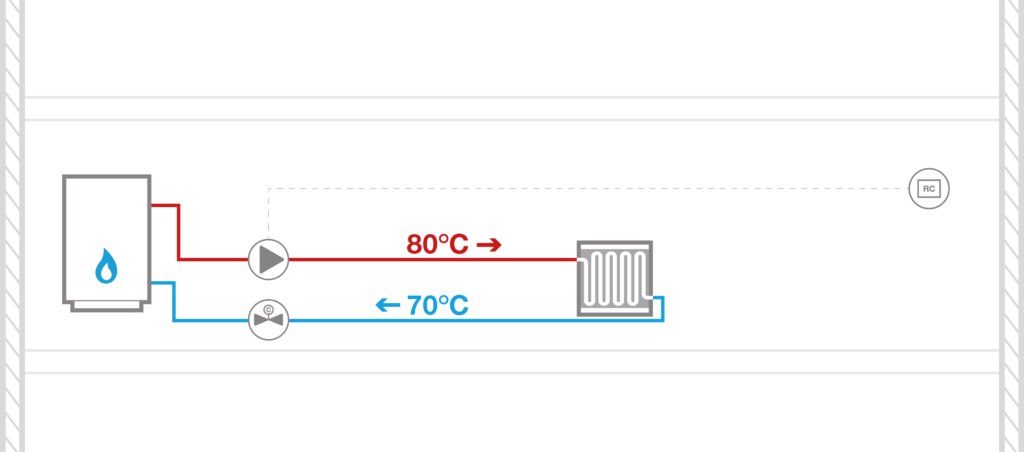

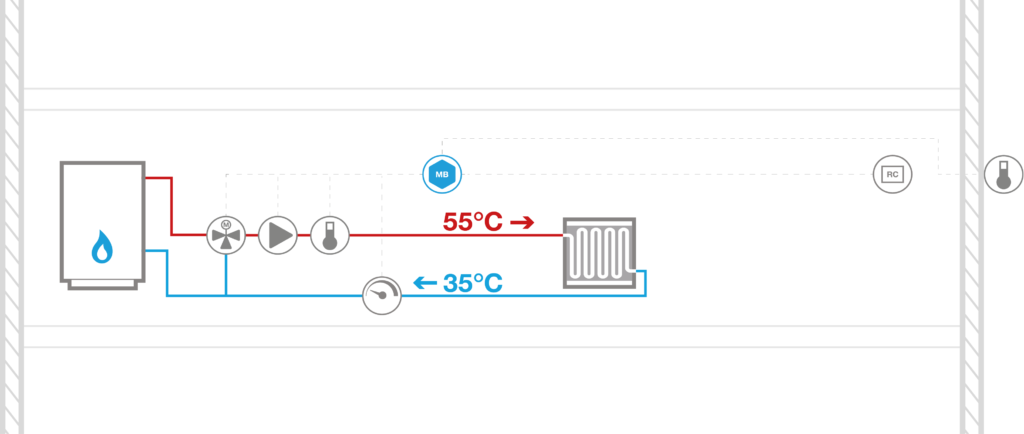

If the system was working to standard design parameters the difference between flow (outgoing water) and return (water going back to the boiler) temperature would be 11 degrees Celsius, whereas at best we generally see a difference of 5 or 6 degrees Celsius. Very efficient systems have a temperature difference between flow and return of over 20 degrees Celsius.

Latest news

Minibems delivers equivalent carbon savings to converting a petrol car to an electric car, for twenty times less capital cost

Reducing our carbon footprint is typically an expensive task requiring extensive capital investment. However installing Minibems onto a heat network typically saves 1 tonne of carbon, per annum, for every apartment it’s fitted into.

Minibems can reduce residents heat tariffs by as much as 22 pence per kWh

With gas prices soaring the opportunity for real and tangible cost savings on heat networks has never been greater.

Cut the carbon in your heat network today

Minibems can cut an average of 1 tonne of carbon emissions per home per annum – saving you money too. By controlling each apartment with our unique and patented Dynamic flow control system we achieve the savings by optimising flow rates through your HIU.

Cut your heat network costs with Minibems

As finance managers across the UK know, managing budgets is a weekly challenge during these unprecedented times for energy price hikes. This isn’t just bad news for those in charge of managing operational budgets for heat networks, it’s also bad news for families.

Interested in finding out how we can optimise your heat network?